Here’s a scenario most concrete manufacturers will be familiar with. Steven is a reputable manufacturer of cement and concrete products with many customers. Although he enjoys great sales, he can’t help but notice that Hans, his Norwegian counterpart, seems to pull even more customers.

Everyone is talking about how strong, fine, and durable Hans’ concrete and cement products are. Intrigued, Steven asks a passing customer one day, “why does everyone rave about Hans’ cement so much?”, and the customer replies, “oh, don’t you know? Hans adds the gray powder into his cement and this makes it so much better!”

“But what is the gray powder?”, wonders Steven. โชคดี, he meets Hans the next day, who tells him, “the gray powder is silica fume”. ตอนนี้, Steven can’t stop thinking about how to get his hands on some silica fume, so his products will be just as good as Hans’.

If you’re also wondering where to buy silica fume, you’re in the right place. ที่นี่, we will explain all you should know about where to buy ซิลิกาฟูม, how it is produced, and how to find the best silica fume on the market.

Major silica fume producing countries

ซิลิกาฟูม is ultra-fine non-crystalline silica that is created as a by-product when manufacturing elemental silicon or ferrosilicon alloys in electric arc furnaces. Also called microsilica, the highly pozzolanic material is widely-used and accepted as a critical additive that strengthens the mechanical and durability of concrete.

Silica fume presents one of the easiest and fastest ways to quickly improve the quality of concrete and cement-based products. Yet, not many cement manufacturers know what this key compound is or why it is so effective. They just know they’ve come across very good cement, but don’t understand why it is so much better than theirs.

Due to the steady creep of development in regions around the world, and the steadily increasing rate of construction, the market for silica fume has grown significantly in recent years. The global silica fume market was valued at $430.87 ล้านใน 2014 and was projected to reach $563.09 ล้านโดย 2020 at a CAGR of 4.22%. Current projections estimate that the market will reach $701.6 ล้านโดย 2025, growing at a compound annual rate of 4.5% ระหว่าง 2020-2025.

Countries in the Middle East and the Asia Pacific dominate the silica fume market due to the massive demands for construction and infrastructure material in those regions. China and India are especially large contributors to the market, along with the UAE in the Middle East. Demand for silica fume has been rising fast in North America though, with the USA leading large amounts of demand within the region.

Some of the major silica-producing countries around the world include China, the USA, ยูเออี, ซาอุดิอาราเบีย, บราซิล, รัสเซีย, นอร์เวย์, แอฟริกาใต้, แคนาดา, ฝรั่งเศส. These countries fuel global demand for silica fume which is used in multiple cementitious and related infrastructure demands.

How silica fume is produced

Despite its applications in several industries, silica fume was not meant for any industrial applications when it was first produced. ในความเป็นจริง, it was treated as a waste by-product in silicon smelting and was usually vented into the atmosphere. อย่างไรก็ตาม, due to tougher environmental laws introduced in the 1960s, silicon smelters started to collect the waste compound, and a short while later, experimentation began in order to find applications of silica fume.

The first tentative tests to find an application for silica fume began in 1952, when it was tested along with fumed silica (very different from silica fume) in Portland cement-based concretes. But in Norway, testing began to indicate that when added to cement-based concretes, silica fume could help produce “very high strengths and low porosities”.

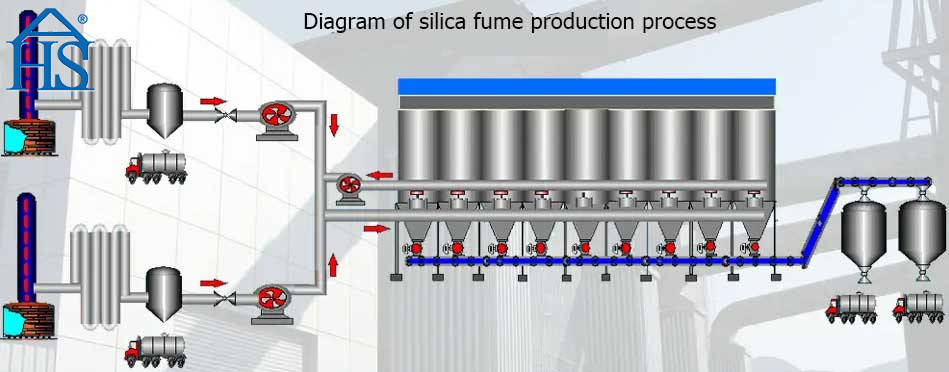

The production of silica fume starts with the reduction of high-quality quartz with coal in electric arc furnaces. The metallurgical-grade quartz is usually combined with wood chips and coal in order to produce silicon and ferrosilicon alloys. These ferrosilicon alloys include ferromanganese, ferrochromium, ferromagnesium, and calcium silicon.

The quartz is reduced to silicon at temperatures up to 2,000 celsius at which point it then produces SiO2 vapors. The vapor, in the form of residue, which is “carried by the exhaust gas from the furnace as oxidized vapor, is then cooled and collected in the form of condensed silica.” This condensed silica fume typically has particles with spherical shapes that are generally smaller than 0.1-1 มม, roughly 100 เล็กกว่าอนุภาคซีเมนต์หลายเท่า.

Silica fume is usually produced as a fine grey powder, usually in very fine powder form. อย่างไรก็ตาม, due to its extremely small weight in this form, the compound may be densified, essentially giving it a density of around 500 kg/m3. Both forms are regarded as dry silica fume.

Increasingly, as a result of concerns over a lung disease called silicosis, silica fume is often provided to concrete manufacturers in slurry form. This not only prevents inhalation of fine, potentially harmful particles, it also potentially enables better dispersion of the silica fume in the concrete mix, leading to a higher quality mix overall.

Silica fume is primarily know and utilized for its concrete-strengthening qualities. Building and construction dominate the market, with a CAGR of 6% จาก 2014 ถึง 2017. In this market, silica fume is applied to concrete because of its ultra-fine quality and high silica content.

When added to cement concrete, it helps improve the compressive strength, ความต้านทานต่อการขัดถู, and bond strength of the concrete. It achieves this due to the pozzolanic reactions it creates with free calcium hydroxide within the cement paste mix. This helps considerably strengthen the properties of concrete in order to create high strength concrete (greater than 50 MPA) and ultra-high-strength concrete (greater than 100 MPA).

It also helps reduce the permeability of concrete, meaning it makes concrete more resistant to moisture seep. This also reduces the susceptibility of concrete to chloride ions, hence protecting the reinforcing steel within the concrete from corrosion. It helps produce the high tensile strength that is critical for the construction of high-rise buildings.

The second biggest industry for the application of silica fume is the marine industry where the compound is used for marine construction. You can often find this being utilized in chloride-rich environments such as drafty continental roadways, coastal environments, and saltwater bridges. Apart from the marine construction industry, silica fume is also often used for oil and gas grouting where it prevents gas migration, increases durability, improves the flow of lubricants and gas, และลดการซึมผ่าน.

Standards of silica fume in various countries

Due to the global nature of the silica fume market, the standards that govern the production of the compound are as homogenous as possible. This ensures generally accepted minimum requirements in the quality, ความปลอดภัย, and efficacy of silica fume, no matter where you are buying around the world.

Despite this, there are often various standards developed by regional or national bodies for the purpose of regulating the production of silica fume within each country. In the USA, there are a few organizations that are responsible for this. They include ASTM International and the American Association of State Highway and Transportation Officials (อาชโต้). Standards commonly applicable within the USA include:

- ASTM C1240

- ACI PRC-234-06

- ACI PRC-549.6-20

- ACI PRC-211.5-14

In the EU, the production of silica fume is governed by the Construction Products Directive (89/106/EEC). Although this was replaced by Regulation 305/2011 ใน 2011. The applicable standards are CAS 69012-64-2 and EINECS 273-761-1. ในบราซิล, applicable standards include ABNT NBR 9778 (2005) and ABNT NBR 15895 (2010).

Determining the standards that apply within your country may be important to identifying the specifications required for your silica fume and assessing which supplier can best meet your needs.

Check out our high-quality silica fume today

ที่ HSA ไมโครซิลิก้า, we provide concrete manufacturers and other industry players with high-quality silica fume that meets production specifications and local standards. Whether what you require is reliable silica fume for construction, อัดฉีดบ่อน้ำมัน, ผลิตภัณฑ์ซ่อมแซม, ultra-high performance concrete, หรือมากกว่า, we have all you need here.

ติดต่อเราวันนี้เพื่อดูว่าเราสามารถตอบสนองความต้องการด้านการผลิตของคุณได้อย่างไร. คุณสามารถขอใบเสนอราคาได้ที่นี่, หรือ ติดต่อเรา to learn more.