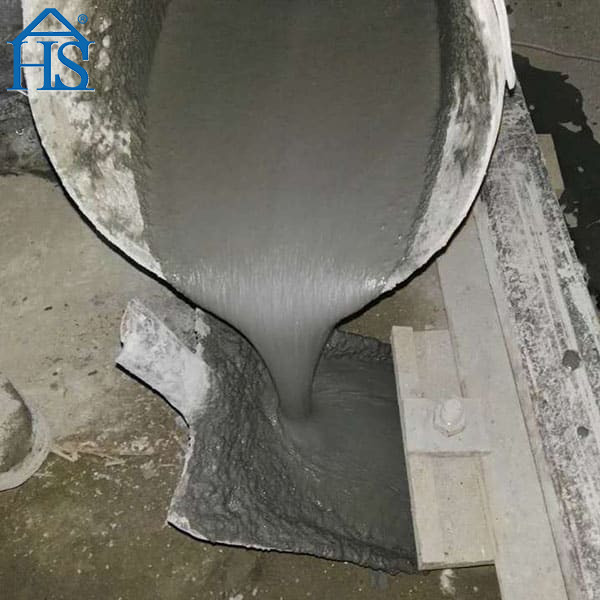

灌浆剂 (材料)

灌浆剂 (材料) 具有优良的微膨胀性能, 不收缩, 大流量, 自压实, 水分分泌率极低, 高填充, 小直径薄气囊泡沫层, 高强度, 防锈和防锈, 低碱无氯, 高粘合力, 绿色环保. 它不含氧化物, 氯化物, 亚硫酸盐和亚硝酸盐, 对钢材有害的成分有哪些, 由高性能增塑剂制成, 表面活性剂, 硅钙微膨胀剂, 水化热抑制剂, 迁移性防锈剂, 纳米级矿物硅钙铝铁粉, 加压浆料或与低碱低热硅酸盐水泥的稳定剂等精制复合材料.

灌浆料中的硅粉

微硅粉 是生产高强无收缩灌浆料的必备原料之一, 压力灌浆及压力灌浆剂, 适用于各种预制梁的灌浆, 支座底板与桥墩支撑垫之间的灌浆, 设备基础二次灌浆, 以及加固和修复.

微硅粉具有早强的优点, 高强度, 自流, 微膨胀, 抗渗油性, 耐用性, 耐候性好, 耐低碱腐蚀性, ETC.

微硅粉会对灌浆料的性能产生很多良好的影响. 无定形和极细硅粉对高性能灌浆料的有益效果体现在以下两个方面: 物理和化学方面:

- 作为超细填料.

- 在早期水化过程中充当晶核,具有较高的火山灰活性.

硅粉在注浆中的特性

1. Accelerate the hydration of the gelling material system

The effect of silica fume on the hydration exotherm of the gelling material system

2. Improve the strength of grout

When silica fume is used with high efficiency water reducing agent, silica fume reacts with hydration product Ca(哦)2 to produce hydrated calcium silicate gel, which fills the gap between cement particles, improves the interface structure and bonding force, and forms a dense structure, thus significantly improving the strength of grout. 一般来说, the amount of silica fume mixed with 5%~10% can produce super high strength grout with compressive strength of 100MPa.

3. Increase density

Silica fume particles are very small and can fill in the gaps between cement particles. The dense accumulation of particles can reduce water secretion, reduce capillary Taiyuan high-strength non-shrink grout and average pore size. The amount of silica fume can get good admixture effect when the admixture is 5%~10%. Water reducing agent should be used to ensure that the silica fume and cement dispersion.

4. Improve grout segregation and water secretion performance

5. Improve the anti-seepage and chemical corrosion resistance of grout

6. The effect of silica powder on the anti-freezing property of grout

Regarding the effect of silica powder on the frost resistance of grout, a large number of studies at home and abroad show that, in the case of equal replacement, the frost resistance of grout with less than 15% admixture is basically the same, and sometimes it will increase (such as when the admixture is 5% 到 10%), but the admixture exceeds 20% 会显着降低硅粉灌浆料的抗冻性.

在高性能灌浆料中, 从减少早期塑性收缩和干燥收缩考虑, 一般控制水泥浆中硅粉掺量总量为一吨胶凝材料的多少以内 10% 金额的, 当气泡间距系数减小时, 抗冻性往往得到提高.

7. 硅粉与碱骨料反应

碱骨料反应是骨料中的活性氧化硅与水泥中的碱发生反应,生成吸水产物,体积增大, 导致灌浆膨胀、开裂. 当硅灰添加到水泥浆中时, the reaction between silica fume and alkali in cement can prevent this excessive expansion.

Domestic and foreign practice shows that silica fume is beneficial to inhibit the alkali-aggregate reaction in grout. When calculating the total amount of alkali in the grout, the effective amount of alkali carried by silica fume is calculated as 50% of its total alkali content.