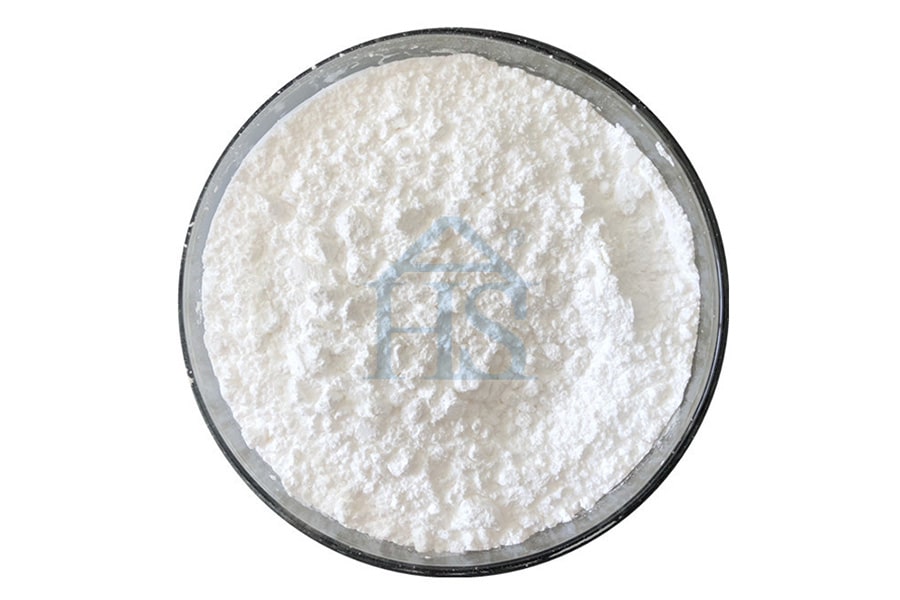

98% Undensified Silica Fume

98% Undensified Silica Fume

- SiO₂: >98%

- Color: White

- PH Value: 4~6

- Bulk density: 200~350kg/m3, 550~650kg/m3, Above 700kg/m3

- Packages:1000kg plastic woven bags, 10kg soluble paper bags, 20kg soluble paper bags, 25kg plastic woven bags, 500kg plastic woven bags, 600kg plastic woven bags, 950kg plastic woven bags

Introduction

98% undensified silica fume, a white microsilica with a silica (SiO₂) content of over 98%, is valuable in a variety of construction applications.

Due to its extremely fine particle size and high purity, 98% undensified silica fume improves concrete properties by increasing strength, durability and impermeability. It is widely used in high performance concrete, shotcrete and refractory materials.

This form of silica fume is undensified, which means it retains its original low bulk density, making it easier to disperse uniformly in concrete mixtures. Due to its high reactivity and ability to improve the overall quality of concrete, it has become a popular choice for demanding construction projects such as bridges, tunnels and industrial floors.

98% Undensified Silica Fume COA

Advantages

Applications

- Water conservancy and hydropower engineering: in the anti-seepage and anti-abrasion parts, after mixing with micro-silica powder, it can greatly improve the anti-seepage, anti-cracking, anti-abrasion and anti-cavitation performance.

- The production of high-strength concrete: silica powder as admixture to make high-strength concrete, the actual application of its strength level can be achieved 100Mpa.

- Seaport engineering: concrete mixed with silica powder can improve the concrete’s anti-abrasion performance, anti-seepage performance, to prevent electrochemical corrosion of reinforcing steel.

- Traffic engineering: silica powder concrete used in highway pavement and aircraft runway, can greatly improve the early strength and wear resistance of concrete, in the maintenance and repair of highway pavement, you can advance the opening time and increase the economic benefits.

- Shotcrete: significantly improve the adhesion performance and cohesion of plastic concrete, significantly reduce the amount of rebound, increase the thickness of shotcrete once formed, shorten the construction period and save the cost of the project.

Packaging

- 10kg soluble paper bags x 84 on the pallets.

- 20kg soluble paper bags x 42 on the pallets.

- 950kg plastic woven bags x 2 on the pallets(with or without bottom spout)

- 1000kg plastic woven bags x 2 on the pallets(with or without bottom spout )

- 500kg plastic woven bags x 2 on the pallets (with or without bottom spout )

The machine is automatically packed and filtered by a screen, so that no debris is mixed in.