At HSA, we take great pride in providing valuable information and expertise on concrete mix ratios. We understand the importance of using the correct concrete mix to achieve optimal strength, durability, and overall performance in construction projects. In this article, we will delve into the details of the proper concrete mix ratio, offering comprehensive insights and recommendations to help you make informed decisions when working with concrete.

Understanding Concrete Mix Ratio

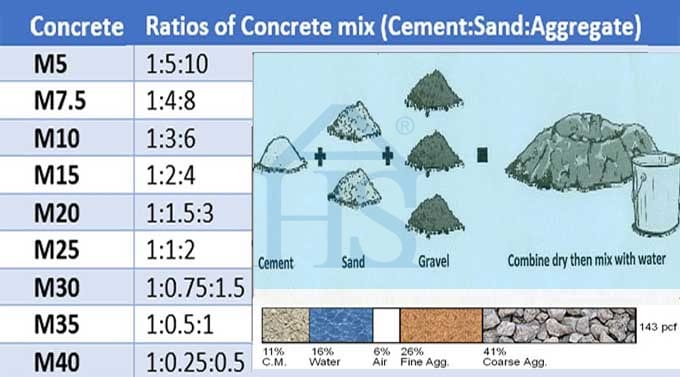

The concrete mix ratio refers to the proportion of different materials used in a concrete mix. These materials typically include cement, aggregates, water, and sometimes additional additives. The correct mix ratio is crucial as it directly impacts the strength, workability, and durability of the resulting concrete.

The Components of Concrete Mix

1. Cement

Cement is a binding agent that holds the concrete mixture together. It provides strength and stability to the final product. The most commonly used type of cement is Portland cement, known for its excellent performance in construction projects. When selecting cement, it is important to consider factors such as cement grade, setting time, and specific project requirements.

2. Aggregates

Aggregates are the inert materials, such as sand, gravel, or crushed stone, that make up the bulk of the concrete mixture. They provide stability, strength, and bulk to the concrete. The size and type of aggregates used can significantly influence the properties of the final concrete, including its workability and strength.

3. Water

Water is a vital component of the concrete mix, facilitating the hydration process of cement and enabling it to bind with the aggregates. The amount of water added to the mix affects the workability, setting time, and strength of the concrete. It is essential to strike the right balance to achieve the desired results.

4. Additives

Additives are optional components that can be incorporated into the concrete mix to enhance certain properties. They can improve workability, reduce water requirements, enhance strength, or provide specific characteristics such as increased resistance to chemicals or improved durability. Examples of additives include plasticizers, superplasticizers, accelerators, and air-entraining agents.

Achieving the Optimal Concrete Mix Ratio

To achieve the optimal concrete mix ratio, it is crucial to consider various factors, including the intended use of the concrete, environmental conditions, and desired strength requirements. Here are some guidelines to help you create a high-quality concrete mix:

1. Determine the Required Strength

Identify the specific strength requirements for your project. This will depend on factors such as the type of structure, load-bearing capacity, and local building codes. Strength requirements typically range from normal strength concrete (around 20-40 MPa) to high-strength concrete (above 60 MPa).

2. Calculate the Proportions

Once you have determined the required strength, you can calculate the proportions of cement, aggregates, and water needed for the mix. It is recommended to use weight ratios rather than volume ratios for accuracy.

A commonly used mix ratio for general construction purposes is the 1:2:4 ratio, which means one part cement, two parts fine aggregates (such as sand), and four parts coarse aggregates (such as gravel or crushed stone). However, it is important to note that specific projects may require different ratios based on their unique needs.

3. Mix Thoroughly and Consistently

When combining the materials, ensure thorough mixing to achieve a uniform and homogeneous mixture. Use proper equipment, such as a concrete mixer, to ensure consistency. Incomplete mixing can result in weak spots or inconsistencies in the final concrete, compromising its strength and durability.

4. Consider Admixtures

Depending on your project requirements, you may choose to incorporate admixtures to enhance specific properties of the concrete. Consult with experts or refer to the manufacturer’s recommendations to determine the appropriate type and dosage of admixtures to use.

Conclusion

The proper concrete mix ratio is vital for achieving optimal strength and durability in construction projects. By understanding the components of concrete mix and following the recommended guidelines, you can create high-quality concrete that meets your specific needs. Remember to consider factors such as required strength, aggregate types, water-cement ratio, and the potential use of admixtures. By adhering to these principles, you can ensure the success of your concrete endeavors.

The diagram above illustrates the general proportions of cement, fine aggregates, and coarse aggregates in a typical concrete mix. Please note that specific projects may require adjustments to these ratios based on individual requirements and engineering considerations.

For further information and expert advice on concrete mix ratios, contact Henan Superior Abrasives. We are here to assist you in achieving the highest quality and performance in your concrete projects.