Silica fume is a revolutionary material that is changing how thermal insulation materials are used. Microsilica fume provides superior insulation performance and energy savings from residential and commercial buildings to industrial applications. We explore the various applications of Microsilica fume in thermal insulation materials and how it can help you save energy and money.

Chemical properties of Silica Fume

Silica fume is a by-product of the production of silicon and ferrosilicon alloys. It is a fine powder composed of amorphous silicon dioxide (SiO2) particles. It is also known as silica fume, condensed silica fume, or pyrogenic silica.

Silica fume has unique chemical properties, making it ideal for various industrial applications.

- Silica is highly reactive and has a high surface area, making it an excellent pozzolanic material.

- It has a low water absorption rate, making it an ideal material for waterproofing and fireproofing applications.

- Its use as a pozzolanic material helps increase concrete’s strength and durability.

- It reduces the permeability of concrete, making it more resistant to water and other liquids.

Property-based applications of silica fume

- Silica fume can also be used in the production of refractory materials.

- The thermal properties of microsilica fume make it an ideal material for use in concrete and other construction materials.

- Its properties also make it an ideal material for use in the production of ceramic materials. It helps increase the strength and durability of ceramic materials, making them more resistant to wear and tear.

- It is also used in glass production. Its presence helps increase the strength and durability of glass, making it more resistant to breakage and other damage.

- It is an ideal material for use in the production of paints and coatings. It helps increase the durability of paints and coatings, making them more resistant to fading and other damage.

- It is useful in the production of adhesives. It works towards increasing the strength and durability of adhesives which makes them more resistant to water and other liquids.

- Its low water absorption rate makes it an ideal material for waterproofing and fireproofing applications.

Benefits of Using Silica Fume in Thermal Insulation Materials

Thermal insulation materials protect buildings and other structures from extreme temperatures. To ensure that these materials are effective, you should use the right type.

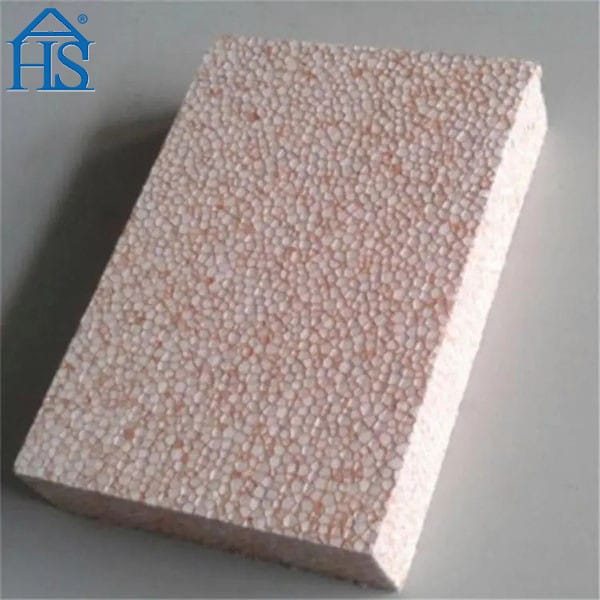

Silica fume is a silica-based material that is useful in thermal insulation applications. It is made up of tiny particles of silica that are suspended in a liquid or gas form. These particles are extremely small, which makes them ideal for insulation purposes.

The benefits of using microsilica fume in thermal insulation materials are numerous:

- It is highly effective at preventing heat transfer. This means it can keep buildings and other structures stable even in extreme temperatures.

- It is also highly resistant to fire, which makes it an ideal choice for fireproofing.

- it is highly durable. It is able to withstand extreme temperatures and other environmental conditions without breaking down.

- It is resistant to corrosion, making it an ideal choice for use in areas where corrosion is a concern.

- Silica fume is also cost-effective. It is relatively inexpensive compared to other insulation materials, making it an ideal choice for those looking to save money.

Overall, microsilica fume is an excellent choice for thermal insulation materials. It is highly effective at preventing heat transfer, durable, and cost-effective.

Silica fume applications in different industry types

-

Application in the cold chain industry

The cold chain industry is vital to the global food supply chain. It is responsible for transporting food products from farm to market, ensuring they remain fresh and safe for consumption. The cold chain industry relies on various materials and technologies to keep food products at the right temperature throughout their journey. Insulation is one of the most critical materials in the cold chain industry. Insulation helps reduce the amount of heat transferred between the environment and the food products during transportation. This helps to keep food products at a safe temperature, preventing spoilage and contamination. Micro silica fume has many advantages over traditional insulation materials. It is light in weight, easy to install, and has low thermal conductivity. This means that it can keep the temperature of the cargo at a more consistent level, reducing the risk of spoilage or damage. Additionally, it is highly resistant to corrosion and can withstand extreme temperatures and moisture conditions. It is also non-toxic and non-flammable, making it a safe choice for use in the transportation of food and other sensitive items.

In the building, micro silica silicate thermal insulation coating is mainly used to insulate internal and external walls. It is usually a fiber-thickened paste that is applied onto the wall surface, and after drying, it gives a strong and flexible insulation layer. It has low thermal conductivity, easy installation, cost-effectiveness, and remarkable heat conservation properties. Furthermore, due to its low thermal conductivity, good insulation, and remarkable thermal insulation properties, the micro silica fume silicate composite thermal insulation wall coating has a high bonding strength, tensile strength, and shear strength and is widely used.

-

Application in power generation

Thermal insulation is critical in power plants, particularly thermal, nuclear, or geothermal energy. It helps save energy, reduce heat loss, adhere to production process requirements, guarantee equipment and personnel safety, and enhance economic and environmental benefits. Silicate composite thermal insulation coatings with micro silica fume are effective for irregularly-shaped components such as valves, elbows, cylinders, tanks, and containers.

-

Application of the cement industry

The microsilica composite silicate thermal insulation coating is applied to the dryer cylinder’s surface, reducing heat loss by over 80%. Additionally, the inner wall of the cylinder avoids moisture build-up and preserves the drying state, thus preventing blockage and acid corrosion, extending the cylinder’s service life. Furthermore, the drying output can increase by up to 15-20%, resulting in an even more visible energy-saving effect, and can be used in open-air pipelines.

-

Application in Food refrigeration

Vacuum insulation panels (VIP) with micro silica fume are a type of insulation material that is used in food refrigeration systems. It is a lightweight material that is highly effective in reducing the thermal conductivity of the refrigeration system. The micro silica fume is mixed with a binder to form a thin film that is then applied to the inner walls of the refrigeration system. This thin film acts as a barrier to the cold air, thus reducing the amount of energy needed to keep the food cold. The micro silica fume also helps reduce the amount of moisture released into the refrigeration system, which helps to minimize the growth of bacteria and mold.

-

Application in the logistics industry (vaccine logistics)

Micro silica fume is an excellent addition to the cold chain of vaccine logistics. It is a highly absorbent material that can keep vaccines and other temperature-sensitive materials cold and safe for an extended period. Micro silica fume is non-toxic and non-flammable, making it an ideal material for the cold chain. It is also lightweight and easy to transport, making it ideal for vaccine distribution. Finally, micro silica fume can absorb moisture, which helps prevent the vaccines from spoiling. Thus, micro silica fume is an essential part of the cold chain that must remain intact to ensure vaccine delivery.

Application of Silica Fume in Thermal Insulation Materials

The application of Silica fume in thermal insulation materials has several advantages:

- It increases the thermal resistance, making it more effective at preventing heat transfer.

- It improves the material’s fire resistance, making it more resistant to fire and heat.

- It increases the material’s durability, making it more resistant to wear and tear.

- It is highly porous, allowing it to absorb and retain moisture, which can help to reduce condensation.

- It has a high surface area, which makes it an effective adsorbent for pollutants. This can help reduce the number of pollutants released into the environment.

Silica fume is an effective way to improve the thermal insulation properties of materials while also providing additional benefits such as fire resistance and pollutant absorption. As energy efficiency standards become more stringent, the use of microsilica fume in thermal insulation materials is likely to become even more widespread.

Advantages of Using Silica Fume in thermal insulation materials

The use of microsilica fume in thermal insulation materials can provide many benefits.

- Lightweight material– Thanks to its lightweight, it is easy to work with and can be used in various applications.

- Water resistant– Micro silica fume is highly resistant to water, making it an ideal material for use in areas prone to moisture.

- Insulator– Its insulation properties provide superior thermal protection. It can help reduce the energy consumed for heating or cooling a building. This can result in significant savings in energy costs over time.

- Environment friendly– It is an environmentally safe material. Its use in thermal insulation materials can help reduce energy costs.

- Durability– It can help reduce the maintenance required to keep the insulation in good condition.

In conclusion, micro silica fume has many applications in thermal insulation materials. It can be used to improve materials’ thermal insulation properties, reduce materials’ thermal conductivity, and increase the fire resistance of materials. Silica fume is also an environmentally friendly material that can be used to reduce energy consumption and improve the sustainability of thermal insulation materials.

Micro silica fume from Henan Superior Abrasives Co., Ltd

With more than 20 years in manufacturing micro silica fume, Henan Superior Abrasives Co., Ltd presents itself as your proffered supplier. We supply high-performance silica products from China. Your requirement for densified and undentified silica fume can be fulfilled in different configurations. Share your project needs, and we will provide you with your custom requirement. Our plants in China can furnish different silica fume configurations on request.

Get your silica fume supplied in custom 1000kg plastic woven bags and 10kg and 20 kg soluble paper bags. Plastic woven bags are also available in small supply quantities. Our high-standard materials find their use in different projects all over the world. We stay committed to delivering the best materials with prompt service.