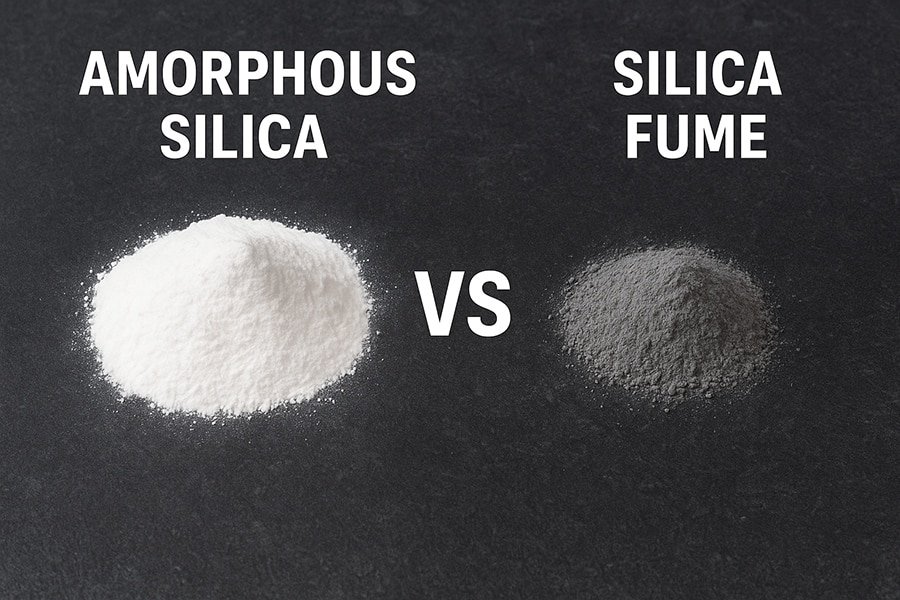

When it comes to industrial silica materials, many people confuse amorphous silica with silica fume. While both are forms of non-crystalline silicon dioxide (SiO₂), they differ significantly in origin, production process, and application.

Definition and Composition

| Item | Amorphous Silica | Silica Fume |

|---|---|---|

| Meaning | A general term for silica (SiO₂) that has no crystal structure — the atoms are arranged randomly. | A specific by-product type of amorphous silica formed during the production of silicon metal or ferrosilicon alloys. |

| Silica Content | 90–99.9% depending on purity and production method | 85–98%, depending on furnace source |

| Structure | Non-crystalline, fine spherical or chain-like particles | Ultra-fine, spherical particles with very high surface area |

In short, silica fume is a special kind of amorphous silica, but produced in a very specific industrial process.

Production Process

Amorphous Silica can be produced synthetically in various ways:

- Fumed silica (gas-phase process) – by burning silicon tetrachloride in hydrogen–oxygen flame.

- Precipitated silica – by acidifying sodium silicate solution.

- Colloidal silica – via sol-gel or wet-chemical methods.

Silica Fume, on the other hand, is a by-product from the electric arc furnace used to produce silicon or ferrosilicon.

When SiO gas is oxidized and condensed in the exhaust gas, it forms ultra-fine amorphous SiO₂ particles, which are then collected by dust filters.

Particle Size and Physical Properties

| Property | Amorphous Silica | Silica Fume |

|---|---|---|

| Average Particle Size | 5–500 nm (depends on type) | ~0.1 µm (about 1/100 the size of cement grain) |

| Specific Surface Area | 50–400 m²/g (especially fumed silica) | 15–25 m²/g |

| Bulk Density | 0.05–0.3 g/cm³ | 0.2–0.7 g/cm³ (densified silica fume can reach 0.6–0.8 g/cm³) |

| Color | White | Gray or dark gray |

Application Differences

| Industry | Amorphous Silica | Silica Fume |

|---|---|---|

| Rubber & Plastics | Reinforcing filler, anti-caking agent | Rarely used |

| Coatings & Paints | Rheology control, matting agent | Not used |

| Electronics & Optical Materials | Used for semiconductors, glass, and ceramics | Not used |

| Concrete & Mortars | Used occasionally in special mixes | Main pozzolanic additive to improve concrete strength and durability |

| Refractory Materials | Sometimes used as bonding agent | Widely used in castables, gunning mixes, and self-flow materials |

Silica fume is mainly applied in construction and refractory industries, while amorphous silica has broader chemical and industrial uses.

Reactivity and Pozzolanic Activity

Silica fume has an extremely high pozzolanic reactivity due to its ultra-fine particles and large surface area. When added to concrete, it reacts with calcium hydroxide [Ca(OH)₂] to form more C-S-H gel, which:

- Increases compressive strength

- Reduces permeability

- Improves chemical resistance

Amorphous silica may also have pozzolanic properties, but its reactivity depends on the production method and particle size — usually lower than that of silica fume.

Key Takeaways

- All silica fume is amorphous silica, but not all amorphous silica is silica fume.

- Silica fume is a by-product of silicon/ferrosilicon production, while other amorphous silicas are synthetic or processed materials.

- Silica fume is preferred for concrete and refractory applications due to its strong pozzolanic activity.

- Amorphous silica is used in chemical, rubber, and electronics industries for entirely different purposes.

Where to Buy High-Quality Silica Fume

If you are looking for a reliable silica fume supplier, Henan Superior Abrasives (HSA Material) offers both densified and undensified silica fume (85%–98% SiO₂) suitable for:

- High-performance concrete (HPC)

- Refractory castables

- Shotcrete and grouts

MOQ: a full container 20ft (about 20 tons)

Our silica fume is tested for pozzolanic activity index, bulk density, and particle distribution to ensure consistent performance.

FAQs

Q1: Is silica fume the same as amorphous silica?

→ No. Silica fume is one specific type of amorphous silica formed during silicon metal production.

Q2: What is the structure of amorphous silica?

→ It has no long-range crystal order — the Si and O atoms are randomly arranged.

Q3: Why use silica fume in concrete?

→ It improves compressive strength, reduces permeability, and enhances durability.

Q4: How much silica fume should be added to concrete?

→ Typically 5–10% by weight of cement, depending on the application.

Q5: Where can I buy high-quality silica fume?

→ You can buy directly from HSA Material, a leading Chinese supplier with consistent quality and competitive price.